In-line inspection systems

EyeC ProofRunner Sheetfed

Improve your print quality direct on your press with EyeC ProofRunner Systems provided by our partners.

Highest Quality sheet for sheet

With our inspection solutions for your sheet-fed offset printing press, you can ensure that 100% of your sheets are checked against an approved template. Misprints, overproduction and complaints are a thing of the past.

Our EyeC inspection systems are available directly from the manufacturer of your printing press. Ask our partners for a customized offer for your new machine. Deliver outstanding quality to your customers from the very first sheet.

- 100 % Inspection

- Outstanding Quality

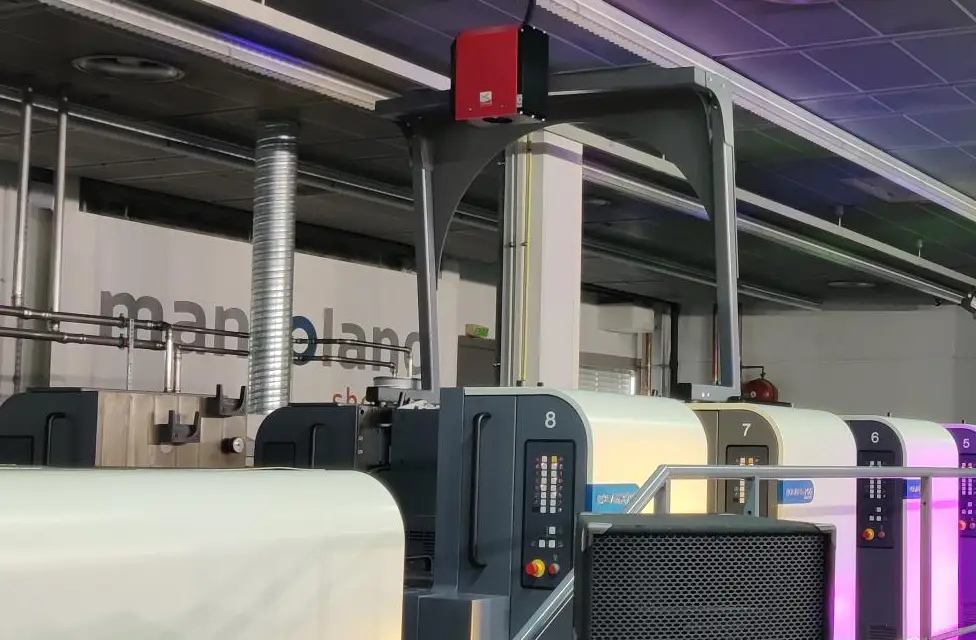

- available from our Partners Koenig & Bauer, Manroland and Landa

- printing press and inspection system tailored to your needs

- AI option to distinguish relevant from non-relevant errors

Do you have an older press for which no inspection system is available?

Talk to us about our EyeC Proofiler offline systems, we also have something suitable for you, for example our EyeC Proofiler 1200 DT.

Key Features

Avoid reclamations and gain new business

Defects in a packaging leads to costly reprints or reclamations.

With our EyeC ProofRunner Inspection systems, print shops can be sure to fulfill their clients’ expectations and keep them satisfied. It also provides them a key sales argument to differentiate from the competition, and win new business.

Reduce waste and cut production costs

Productivity is the key to facing the increasing competition. Our EyeC ProofRunner Sheetfed inspection system reduces costs and save machine time.

By finding defects in real-time, the system allows the operator to correct the problem while printing. By counting the number of good items produced, it also eliminates the need for overruns.

100% Inspection, 100 % Safety

Our EyeC ProofRunner Sheetfed uses high speed line scan cameras and a high-performance computer system to continuously verify the printed quality. Thanks to its easy job set-up, high inspection speed, and accurate defect detection, it offers best-in-class performances.

Even if operated at maximum press speed, the system detects the smallest defects. As a result, jobs are processed and proofed without slowing down production.

Easy to use

Our Inspection system is designed with ease of use in mind, its intuitive interface - available in all major languages - allows any operator to perform a meaningful in-line inspection easily.

Thanks to our intelligent technology, only alerts the operator in case of significant deviations, so so that the operator can focus on the essentials. At the end of the print run, you get a full inspection report automatically, offers managers a perfect tracking, analysis, and communication support.

FAQ

What is ProofRunner Sheetfed?

The ProofRunner Sheetfed from is designed for 100 % inline sheet inspection during printing – on a variety of sheetfed offset presses.

What tasks does ProofRunner Sheetfed fulfil?

EyeC’s ProofRunner Sheetfed module checks the quality of the print job, compares it with the customer’s artwork, and alarms in case of defects. The EyeC ProofRunner Sheetfed enables print shops to improve print quality cost-effectively and flexibly while reducing production costs.

How can ProofRunner Sheetfed reduce complaints?

For example, a mistake in a package leaflet is particularly serious. The consequences for the pharmaceutical industry can be considerable. With the ProofRunner Sheetfed module, faulty sheets can already be detected during printing – before delivery. As a print shop, this enables you to meet your customers’ requirements and avoid costly reprints or complaints.

What are the benefits of ProofRunner Sheetfed?

By checking the quality of the sheets while they are being printed, you not only avoid reprints and complaints due to errors. You can also compete against the competition and increase your sales, as Sheetfed reduces your production time and costs. The system can identify errors in real time so that they can be corrected quickly. This prevents high material waste. Sheetfed also counts error-free items to avoid overproduction. This means you don’t waste expensive materials or valuable press time.