Proofiler Graphic

A prepress inspection system that secures prepress processes and ensures the production of error-free press-ready files.

Off-line inspection systems

The EyeC Proofiler product line is a complete range of off-line inspection systems that help you to ensure the quality of all types of your printed samples.

Do you need a fast and accurate Braille Inspection?

READ MORE >>

Our EyeC Proofiler product line brings you security, efficiency and flexibility to all your QC checks. From DIN A4 to Large Format Print Sheets – we have the perfect solution for you.

By verifying print quality and ensuring content integrity, our print inspection systems helps companies cope with strict requirements, and catch print defects before they generate losses and damage their image.

The EyeC Proofiler combines the power of intelligent software with the performance of a high-resolution scanner.

The inspection system digitally compares the scanned samples against the signed-off proof (typically a PDF file). The operator can easily check deviations and make sure that the samples’ quality complies with requirements.

The inspection is simple, fast, impartial, and reproducible.

Results are fully documented for perfect traceability.

At a print shop, the EyeC Proofiler system can be used to check the first print, perform regular inspections while the press is running, or verify quality before shipping material to customers. Potential problems are detected in a early stage, efficiently reducing waste, and avoids costly reprints or reworks.

For incoming packaging control, the EyeC Proofiler allow you to perform reliable and efficient incoming quality control. Make sure that your quality standard has been met, uphold a consistent brand image, and that your packaging complies with regulations.

Avoid costly product recalls, while keeping up with tight production schedules.

Every EyeC Proofiler comes with a very fast, system-tailored high resolution scanner. Verify the the content against the signed-off proof (typically a PDF file). Check Texts, graphics, color deviations, printed 1D and 2D codes, as well as embossed and printed Braille on all of the scanned samples in just one inspection cycle.

The EyeC Proofiler identifies all defects with high precision, such as color deviations, mis-registers, press contamination, filled in characters, hickeys, poor quality codes or defect Braille dots. With our system, you get a reliable verification in any language, tailored to your needs.

Our fast EyeC Proofiler systems offers a first-classs solution for quality control. Thanks to its high level of automation and performant hardware, our EyeC Proofiler drastically reduces inspection time. Even composite jobs, for instance front and back labels, can be checked against their corresponding PDFs in one click. With our EyeC Proofiler product line, you can combine efficient workflows and sustainable production. Avoid waste and preserve your resources.

The EyeC Proofiler product line complies with all necessary guidelines and regulations. If you are a Pharmaceutical Company or in the Food & Beverages Industry – we understand your needs. FAT, SAT, IQ; OQ and PQ are are no foreign words for us - we understand your requirements and offer you a extensive package from sample URS and Acceptance Procedures to PQ support. Talk to our validation experts!

A prepress inspection system that secures prepress processes and ensures the production of error-free press-ready files.

Our entry-level model for occasional inspections – artwork inspection up to A4 size.

Whether print sample testing or incoming goods inspection – the EyeC Proofiler 400/600 DT offers you ultra-fast and precise inspection.

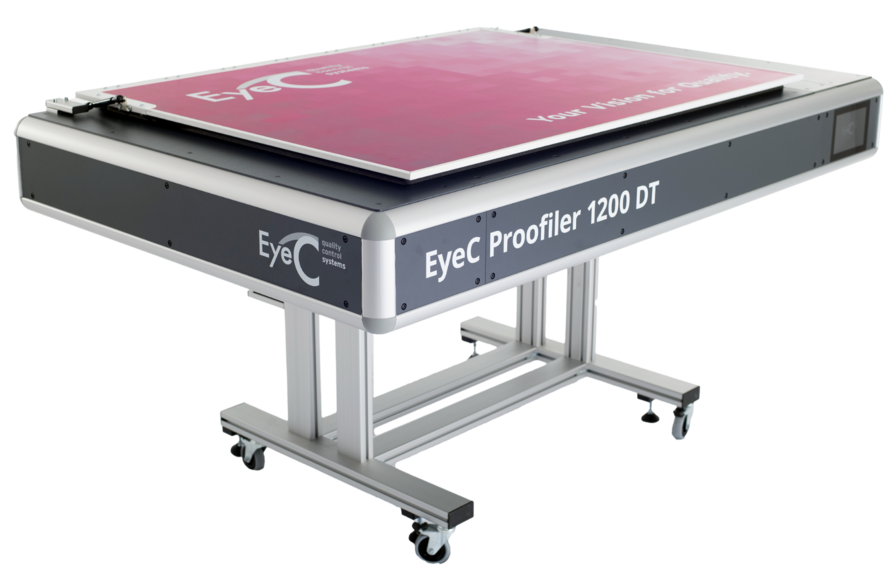

The EyeC Proofiler 1200 DT sets new standards in quality control for wide format print pattern control.

Our solution for large-format printed sheets – without compromising on inspection performance.

The reliable pull-through scanner requires very little space, therefore fitting into tight workspaces.

The EyeC Proofiler detects various types of errors, including colour deviations, missing or shifted text, incorrect barcodes, image errors and other inconsistencies in the printed image.

The EyeC GmbH maintenance service includes regular inspections, software updates and calibrations. These preventive measures help to maintain the performance and accuracy of the inspection systems in the long term and minimise downtimes.

Yes, the EyeC Proofiler is able to check variable data such as serial numbers, batch numbers and expiry dates. This is particularly important for traceability and product safety in the pharmaceutical and food industries.

Yes, the EyeC Proofiler can be easily integrated into existing quality control processes. The software is compatible with common pre-press and production systems and can be flexibly adapted to individual requirements.

Thank you for your interest in EyeC.

We’ll get back to you as soon as possible.

Callback-Request

Thank you for your interest in EyeC.

We’ll get back to you as soon as possible.